What Materials can UV Printing be Used For?

In this Article

Table of Contents

- INTRODUCTION

- Personalize Awards, Trophies, And Commemorative Gifts

- Custom Mobile Phone Cases

- Vehicle Graphics

- Signs And Graphics

- Vinyl Banner

- Pen & Pencil Printing

- Printed Golf Balls

- Bottle & Glass Printing

- Keyring Printing

- Plastic Cards

- Printed Stickers

- Vinyl Printing

- Wood Printing

- Corrugated Plastics & Foam Printing

- Is UV printing right for your project?

- REQUEST A FREE QUOTE

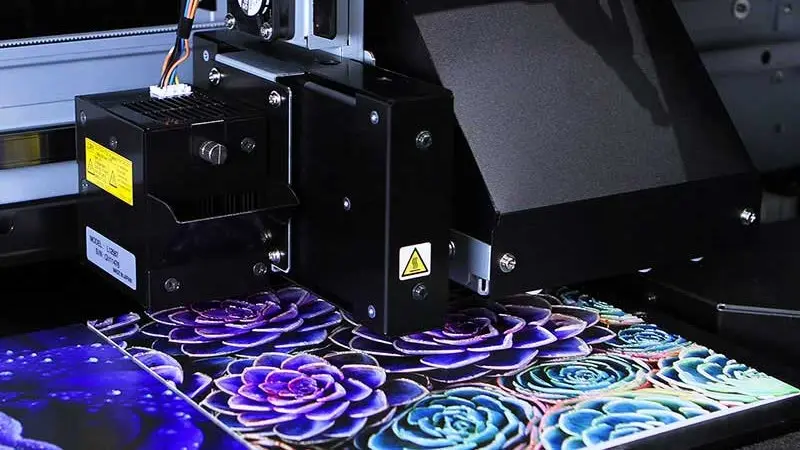

UV printing technology has evolved gradually over time and is becoming the preferred method of printing for a wide variety of printing applications, from labels and packaging to signs and displays.

Some of the most common applications for UV printing include signage, packaging, and labels. UV printing is also frequently used for printing on glass, plastics, and metals.

Personalize Awards, Trophies,

Awarding gifts and trophies to someone is a way of appreciating their excellence in a particular field. It acts as a source of inspiration for people to give their best. If you are looking for a gift that is unique and memorable, then you should consider UV printing.

UV printing is perfect for those who want to personalize awards, trophies, and commemorative gifts. Unlike other printing methods, UV printing can print on any substrate, regardless of size, shape, or thickness.

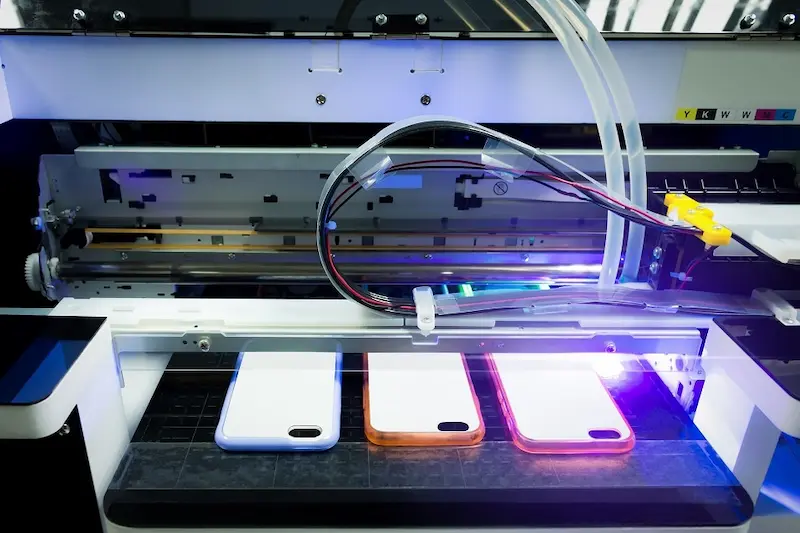

Custom Mobile Phone Cases

UV printing is one of the most popular methods for printing custom mobile phone cases. This printing method is popular because it is very versatile and can be used to print on a variety of materials, including plastic, metal, and glass.

UV printing is also very durable, so your printed mobile phone case will last for many years.

If you are looking for a custom mobile phone case, then you should consider using UV printing. This printing method can provide you with a high-quality and long-lasting printed mobile phone case.

Vehicle Graphics

One of the most popular applications for UV printing is vehicle graphics. Vehicle graphics are a great way to promote your business and get your brand out there.

With UV printing, you can produce high-quality, long-lasting vehicle graphics that will turn heads and get people talking.

Signs And Graphics

UV printing is a great option for signs and graphics because it is a very durable printing method. The inks used in

UV printings are also very resistant to fading and are very vibrant.

If you are looking for a printing method that is versatile, durable and produces high-quality signs and graphics, then UV printing is the perfect option for you! light to cure or “dry” inks as they are printed.

This printing method is also known as direct-to-media or flatbed printing.

UV printing is ideal for a wide range of Sing & Graphic applications, including:

– Glass and metal

– POP displays

– Ceramics

– Wood

Vinyl Banner

Vinyl banners are one of the most popular promotional tools used by businesses today. They are durable, eye-catching, and relatively inexpensive to produce. And, thanks to advancements in printing technology, they can now be printed using UV inks.

UV inks are more resistant to fading and are ideal for outdoor use. They also allow for a wider range of colors and finishes, giving you more options for your banner design.

Pen & Pencil Printing

Personalized pens are a great way to promote your business, brand, or event. They are also a great way to show your appreciation to your employees, clients, or customers.

UV printed pens are very durable and have a high-quality print. This makes them ideal for promotional purposes.

If you are looking for a unique and cost-effective way to personalize pens, then UV printing is the way to go.

Printed Golf Balls

UV printing is a great way to customize golf balls because it is a very versatile printing process. UV printing can be used to print on golf balls of all sizes, shapes, and colors. UV printing can also be used to print on golf balls with different textures and patterns.

Bottle & Glass Printing

Customized Bottle & Glass Printing using UV printing is a process in which a design is printed onto a bottle or glass object using UV-curable ink. This method is ideal for small batch orders and offers a wide range of benefits over traditional screen-printing methods

Some of the main benefits of UV printing include:

– Increased durability and scratch resistance

– Vibrant and crisp colors

– Quick drying time

– Ability to print on a variety of materials

Keyring Printing

Are you looking for a way to print unique, durable keyrings? If so, consider using the UV printing method. UV printing is a popular printing method that uses ultraviolet light to cure the ink.

This printing method is ideal for printing keyrings because it is durable and can produce high-quality prints.

Plastic Cards

Are you looking for high-quality, unique, and durable Plastic Cards? Then you need to try UV printing! This printing method is perfect for plastic cards because it produces sharp images and can print on any type of material.

At The Teeser, we offer UV printing services for plastic cards. We use state-of-the-art equipment to produce high-quality prints that will last for years.

We also offer various printing options to choose from, such as single-sided printing, double-sided printing, and more.

Printed Stickers

UV printing is a great option for businesses that need high-quality printed stickers. With this printing method, businesses can get printed stickers that are durable, long-lasting, and resistant to fading and smudging.

Vinyl Printing

Vinyl printing is a process in which ink is transferred onto a substrate via a mesh screen that has been coated with a light-sensitive polymer. The mesh screen is exposed to ultraviolet (UV) light, which hardens the ink and allows it to be transferred to the substrate.

This printing method is often used for stickers, banners, and signs. However, it can also be used for other applications, such as wall graphics, magnets, and window clings.

UV printing is a versatile printing method that offers several benefits, including high image quality, durability, and versatility.

Wood Printing

The process of printing on wood has come a long way since the early days of block printing. With the advancement of technology, there are now more efficient and less time-consuming methods of printing on wood.

Wood UV printing uses ultraviolet (UV) light to cure inks and create a permanent bond between the ink and the wood. This printing method is also known as direct printing or flatbed printing.

UV printing is ideal for printing on wood because it produces sharp, vibrant prints that are resistant to fading and wear.

Corrugated Plastics & Foam Printing

Corrugated plastics are versatile substrates that can be used for a wide range of applications. One of the most popular applications for corrugated plastics is print. Corrugated plastics are perfect for print because they are strong, lightweight, and durable.

Is UV printing right for your project?

– When You Care About The Environment

The popularity of UV printing has been on the rise in recent years, and it’s no wonder why. This printing method has a number of advantages, chief among them being its environmental friendliness.

In traditional printing methods, such as offset printing, a significant amount of ink is wasted. This is because the excess ink is wiped off the plate before it is transferred to the paper. With UV printing, however, the excess ink is cured, or dried, with ultraviolet light before it is transferred to the paper. This means that there is very little ink waste.

In addition, traditional printing methods use a considerable amount of water. The paper must be dampened before it is fed through the press, and this water can contain harmful chemicals. UV printing, on the other hand, does not require dampening and, as a result, uses very little water.

For these reasons, UV printing is a more environmentally friendly option than traditional printing methods. If you are concerned about the impact of your printing on the environment, UV printing is the way to go.

– When You Need “It” Fast!

UV printing is a type of digital printing that uses ultraviolet light to Cure or dry inks. It is considered as one of the fastest methods in the digital printing process. In comparison to other digital printing methods, such as, drop-on-demand, UV printing is up to two to three times faster.

– When A Specific Look Is Desired

UV printing is perfect for projects that need one of two looks. The first look is a glossy, high-quality finish that is perfect for product labels, marketing materials, or any project that needs to look its best.

The second look is a more subtle matte finish that is perfect for textured surfaces or any project that needs a more understated look.

UV printing is also perfect for projects that need to be durable or waterproof. UV inks are cured, or “dried,” by UV light, which means they are more resistant to smudging, scratching, and fading.

This makes UV printing perfect for projects that will be exposed to the elements or handled frequently.

– When Smudging Or Abrasion Is A Concern

UV printing, or ultraviolet printing, is a printing process that uses ultraviolet light to cure or dry ink. UV printing is great for harsh environments because the light + ink combination creates a durable, long-lasting print.

UV printing is often used for outdoor applications, such as signages and banners because the result is resistant to sunlight, water, and other elements. The cured ink also has higher abrasion resistance, making it ideal for high-traffic areas.

– When Printing On Plastic Or Non-Porous Substrates

When it comes to print, one size does not fit all – and that’s especially true when it comes to the substrate you’re printing on. But with so many different printing technologies out there, how do you know which one is best for your project?

One printing technology that is well-suited for printing on plastics and other non-porous materials is UV printing. UV printing uses ultraviolet light to cure ink, which results in a strong bond between the ink and the substrate.

This makes UV printing ideal for printing on materials that are difficult to print on, such as plastic and metal.

Are there any drawbacks to UV printing?

As a consumer, there is no real downside to choosing UV printing for your next project. The quality of the printing and the durability of UV printing are outstanding.

The only concern at this time would be the slight increase for UV printing as it is still considered a new technology and many print shops will need to cover their initial capital investment costs.